There are several steps you can take to test whether your 2-stroke oil pump is functioning correctly. One is to check the oil level in the tank. If it’s low, then the pump isn’t working.

Another way to tell is by starting up the engine and listening for a ticking sound. This sound indicates that the pump is working. Finally, you can remove the spark plug and look at the color of the deposit on it.

If it’s blue or light gray, then there’s enough oil getting through the pump.

- Check the oil level in the tank to make sure it is full

- Start the engine and let it warm up for a few minutes

- Listen for any strange noises coming from the engine area

- If you hear any, shut off the engine immediately and check for leaks

- With the engine running, observe the oil pressure gauge or light (if equipped)

- The needle should be in the normal range, or the light should be green or blue

- If it is not, shut off the engine and check for leaks

How Do You Test a 2-Stroke Outboard Oil Pump?

Assuming you are referring to a piston port 2-stroke, the most common and effective way to test a 2-stroke outboard oil pump is by using a compression tester. This will help you identify if the pump is working correctly and delivering the correct amount of oil to the engine.

To use the compression tester, remove all spark plugs from the engine and screw the compression tester into the first cylinder. Have someone crank the engine over slowly while you observe the gauge. If it reads below 100 PSI, then there may be an issue with your oil pump.

How Does Oil Injection Work on a 2-Stroke Outboard?

2-stroke outboards have an oil injection system that lubricates the engine by injecting oil into the crankcase. The oil is then drawn up into the cylinder through the piston rings, lubricating the engine components as they move. This system eliminates the need to mix oil and gas, which can be a messy and challenging process to perform correctly.

The oil injection system on a 2-stroke outboard has several key components: • An oil reservoir – this is where the oil is stored before being injected into the engine. • A pump – this pumps the oil from the reservoir to the injectors.

• Injectors – these inject the oil into the engine at specific times during operation. • A controller – this regulates when and how much oil is injected into the engine based on information it receives from sensors. The way it works is pretty simple:

1) Oil is drawn from the reservoir by the pump and delivered to the injectors under high pressure. 2) The injectors spray small droplets of oil directly onto critical engine components, such as bearings and cylinder walls. 3) As these surfaces get hot during operation, some of the sprayed oil evaporates, providing a cooling effect in addition to lubrication.

How Do You Bleed a 2 Stroke Oil Pump?

To bleed a 2-stroke oil pump, you will need the following tools: a screwdriver, a wrench, and a container to catch the oil. First, locate the bleed screw on the side of the pump. Next, use the wrench to loosen the bleed screw until oil begins to drip out.

Be careful not to over-tighten the bleed screw, as this can damage the pump. Finally, use the screwdriver to adjust the tension on the spring inside the pump until it is properly bled.

Why Do Some 2-Stroke Engines Use Oil Injection?

Most two-stroke engines use a mixture of gas and oil, but some newer models have oil injection. Oil injection systems automatically add oil to the fuel mix, eliminating the need to premix your fuel. Oil injection has a few advantages over premixed fuel.

First, it’s more convenient because you don’t have to mix the fuel yourself. Second, it can help improve engine performance because the oil is more evenly distributed throughout the cylinder than with premixed fuel. Additionally, it can extend engine life by reducing wear on piston rings and other engine components.

So why doesn’t everyone use oil injection? There are a few reasons. First, it’s more expensive than premixed fuel.

Second, it requires regular maintenance to keep the system clean and operating properly. And third, some people prefer the simplicity of premixed fuel.

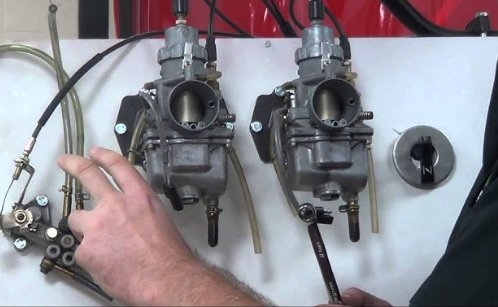

How to service 2 Stroke Oil Injection System How to prime oil injection pump #how2wrench #2stroke

2 Stroke Oil Pump Adjustment

If you own a two-stroke engine, it’s important to know how to adjust the oil pump. This will ensure that your engine receives the proper amount of lubrication, helping to prolong its life. Here’s a step-by-step guide on how to do it:

1. Start by removing the oil cap from the engine. This will give you access to the oil pump adjustment screw. 2. Use a wrench to loosen the locknut that secures the adjustment screw in place.

3. Turn the adjustment screw clockwise or counterclockwise until you achieve the desired oil flow rate. Be sure not to over-tighten the screw, as this can damage the pump. 4. Once you’ve achieved the desired flow rate, tighten down the locknut and replace the oil cap.

How to Tell If Oil Injection is Working on Outboard

If you have an outboard boat motor, it is essential to know how to check if the oil injection system is functioning correctly. This system automatically adds oil to the fuel, which is what keeps your engine lubricated. If it isn’t working properly, your engine could overheat or seize up.

Here are a few things to look for: 1. Check the oil level in the tank. It should be full.

If it’s low, then the system isn’t injecting oil into the fuel. 2. Look at the color of the oil in the tank. If it’s black and gritty, then the system isn’t filtering the oil properly, and it’s going into your engine dirty.

This can lead to various problems down the road. 3. Check for leaks around the oil injector pump and fittings. These are common places for leaks to occur if there is a problem with the system.

4. Listen to your engine while it’s running.

Oil Injected 2 Stroke Outboard

An oil-injected 2-stroke outboard engine is a type of outboard engine that utilizes a mixture of oil and gasoline. The oil is injected into the engine, where it lubricates the moving parts. The gas powers the engine, and the oil helps to keep it running smoothly.

This type of outboard is more expensive than a traditional 2-stroke outboard, but it is more fuel efficient and produces fewer emissions.

2 Stroke Oil Injection Delete

Greetings, fellow two-stroke enthusiasts! In this post, we will be discussing the pros and cons of deleting your two-stroke oil injection system. This is a highly controversial topic in the world of two-stroke engines, so we hope to provide some clarity on the situation.

Let’s start with the basics: What is an oil injection system, and why would someone want to delete it? An oil injection system is a method for delivering lubricating oil to the engine without requiring manual mixing with fuel. This offers several benefits over premixing, including more consistent lubrication and less waste.

However, there are also some drawbacks, most notably, increased cost and complexity. So, what are the arguments for deleting your oil injection system? The biggest one is weight savings.

Every ounce counts when you’re trying to go fast, so shedding unnecessary weight can be a big advantage. Additionally, many riders feel that they get a better sense of connection with their machine when they manually mix their own fuel and oil ratio. There is also the potential for a slightly increased power output, although this is often offset by decreased reliability.

On the other hand, there are several good reasons to keep your oil injection system intact. Firstly, it’s much easier and less messy than premixing – no more spilled fuel or oily clothes! Secondly, it provides peace of mind knowing that your engine is always properly lubricated (this can be especially important if you ride in dusty or sandy conditions).

Finally, modern systems are generally very reliable – provided you keep up with regular maintenance like changing the filter and replenishing fluids as needed.

Conclusion

If you own a two-stroke engine, it’s essential to know how to check if the oil pump is functioning correctly. The oil pump is responsible for delivering oil to the engine’s moving parts. Without adequate lubrication, the engine will quickly wear out.

There are several ways to determine if the oil pump is functioning correctly. First, check the oil level in the crankcase. If it’s low, that’s an indication that the pump isn’t working correctly.

Next, check for leaks around the pump. If there are any, that means the oil isn’t being delivered properly and needs to be fixed as soon as possible. Finally, listen to the engine while it’s running.

If you hear any strange noises coming from inside, that could be a sign that something is wrong with the oil pump.

Leave a Reply