If you’re not sure whether your outboard’s oil injection system is working, there are a few things you can check. First, look for any obvious leaks in the system. If there are no leaks, then check the oil level in the reservoir.

If the oil level is low, topping it off may resolve the issue. If the problem persists, then you may need to take your outboard to a mechanic for further diagnosis and repair.

- Inspect the oil reservoir to ensure that it is full

- If it is low, add more oil until it reaches the “full” line on the side of the reservoir

- Start the outboard and let it idle for a few minutes

- Observe the color of the exhaust smoke coming from the engine

- If it is black or blue, this indicates that oil injection is not working correctly, and you will need to mix your fuel and oil manually

How Does Oil Injection Work on an Outboard Motor?

An outboard motor is a propulsion system for boats, consisting of a self-contained unit that includes an engine, gearbox, and propeller or jet drive, designed to be affixed to the outside of the transom. They are the most common method of secondary propulsion on sailboats after the onboard engine. Outboard motors can be propelled by gasoline, diesel, compressed natural gas (CNG), alcohol fuels, or electricity.

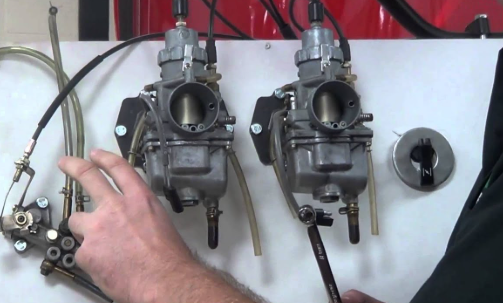

How does oil injection work on an outboard motor? Oil injection systems were introduced in the early 1970s as a way to provide constant lubrication to an outboard engine, eliminating the need for premixing fuel and oil. Early models were unreliable and often injected too much oil into the engine, resulting in fouled spark plugs and excessive smoke.

However, modern oil injection systems are much more reliable and efficient. Most outboards today are two-stroke engines that require a mixture of gasoline and oil to run. The oil is mixed with gasoline at a ratio typically between 50:1 and 100:1; this means that for every gallon (or liter) of gas, you would add 2.6 ounces (or 75ml) of oil, up to 1.3 ounces (or 38ml) of oil.

Using too little oil in the mix will result in insufficient lubrication and increased wear on the engine, while using too much oil will cause fouling of spark plugs and excessive smoke. With an oil injection system, however, there is no need to premix fuel and oil; instead, oil is automatically injected into the combustion chamber at set intervals, determined by sensors within the system, during operation. This provides consistent lubrication to the engine, eliminating concerns about excessive or insufficient oil in the mixture, which reduces the likelihood of mechanical problems and improves overall performance.

How Does Oil Injection Work?

Oil injection is a system used on two-stroke engines that injects oil into the engine cylinder to lubricate the engine. The oil is injected under high pressure into the engine through a small hole in the cylinder’s side. The oil then mixes with the fuel and burns along with it, providing lubrication for the engine’s moving parts.

Oil injection has several advantages over other methods of lubricating two-stroke engines, such as premixing oil and fuel or using an external oil pump. It eliminates the need to manually mix fuel and oil, which can be a messy and time-consuming process. It also reduces wear on engine components by delivering a constant supply of fresh, clean oil to them.

Ultimately, it enhances combustion efficiency and power output by facilitating the more complete combustion of fuel and oil.

How Do You Prime an Oil Injection?

If your outboard has an oil injection system, you don’t have to mix the fuel and oil yourself. The engine will automatically inject oil into the cylinders at the correct ratio. However, before you can start using the oil injection system, you need to prime it.

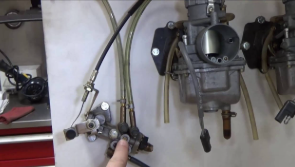

Priming the system involves filling all the lines and components with oil, ensuring that when you start the engine, there are no dry areas where oil should be present. Here’s how to do it: 1) Fill up the oil reservoir with two-stroke outboard motor oil.

If you’re not sure how much to put in, consult your owner’s manual. 2) Open the bleed screw on the side of the reservoir and let some oil come out until you see it dripping from the bleed screw. This is important because it eliminates any air bubbles in the line.

3) Close the bleed screw and ensure that all hoses are properly connected without any leaks. 4) Now it’s time to prime the system. Start by inserting your key into the ignition and turning on the power switch or button (consult your owner’s manual if you’re unsure where this is located).

Then, push down on the primer bulb a few times until you see resistance. You should also hear a clicking sound coming from the engine area, as well as feel some resistance in the primer bulb itself when you push down on it. This means that it’s working properly. Once you’ve done this a few times, turn off the power switch/button again.

5) Next, locate your choke knob/lever (again, consult your owner’s manual if needed) and move itto either “full” or “on” position – again, this will depend on what model of outboardyou have so consult your ownersmanual for clarification if needed.”Full” usually means that it’s all theyway up while “on” usually means thatit’s about halfway up – but once again,- checkyour owners manual! After moving the choke lever to either “full” or “on”, push down on the primer bulb 5-10 more times until resistance is felt again, and then release it slowly.

Is Yamaha Oil Injection Reliable?

Yamaha’s oil injection system is one of the most reliable on the market. It uses a separate tank for oil, which is constantly injected into the engine during operation. This means that you don’t have to premix your fuel and oil, saving you time and hassle.

How to Inspect and Prevent Failure of Yamaha Outboard Oil Injection System

Mercury Oil Injection System Troubleshooting

If you’re experiencing trouble with your Mercury oil injection system, there are several steps you can take to troubleshoot the issue. First, check the oil level in the reservoir. If it’s low, add more oil.

Next, check the condition of the oil pump drive belt. If it’s damaged or worn, replace it. Finally, check the oil injectors for blockages or leaks.

If you find any issues, clean or replace the injectors as needed.

How Does Oil Injection Work on a 2 Stroke Outboard

Oil injection on a 2-stroke outboard engine works by mixing the oil and gas before they enter the engine. This is accomplished by a pump driven by the engine itself. The oil and gas are then injected into the cylinder through special injectors.

The mixture of oil and gas then burns, providing lubrication and power to the engine.

2 Stroke Outboard Oil Reservoir

Most outboard motors are equipped with some form of oil reservoir. The 2-stroke outboard oil reservoir is no different and serves an important purpose in the operation of your motor. Here’s what you need to know about this essential component.

The 2-stroke outboard oil reservoir is responsible for holding a supply of oil that is used to lubricate the engine. This oil helps to keep the engine cool and prevents friction between moving parts. It is essential to check the oil level in the reservoir regularly, as low levels can cause engine damage.

Topping up the oil level in the 2-stroke outboard oil reservoir is a simple task that most people can easily do. However, it is worth noting that overfilling the reservoir can cause problems, so it is best to follow the manufacturer’s instructions carefully. If you notice that your 2-stroke outboard motor isn’t running smoothly or if you see any signs of leaking, there’s likely a problem with the oil reservoir.

In such cases, it is best to seek professional help to prevent further damage to your engine.

Yamaha Outboard Oil Injection Troubleshooting

If you’re experiencing trouble with your Yamaha outboard oil injection system, there are several steps you can take to troubleshoot the issue. First, check the oil level in the tank. If it’s low, add more oil until it reaches the full line.

Next, check the oil filter and replace it if it’s clogged. Finally, check the oil pump for any leaks or blockages. If everything appears to be in order, but you’re still experiencing issues, take your outboard to a qualified technician for further diagnosis and repair.

Conclusion

If you have an outboard motor, it’s essential to know how to determine if the oil injection system is functioning correctly. This system helps keep your engine lubricated and running smoothly. Here are a few things to look for:

1. Check the oil level in the tank regularly. If it drops too low, it could be a sign that the oil isn’t being injected into the engine properly. 2. Listen for any unusual noises coming from the engine.

If you hear anything unusual, it could be a sign that the oil injection system isn’t working correctly. 3. Monitor your engine’s performance closely. If you notice any changes in power or efficiency, it could be a sign that something is wrong with the oil injection system.

If you’re having any problems with your outboard motor’s oil injection system, be sure to take it to a qualified technician for service.

Leave a Reply