To test an oil pressure gauge, you will need a few tools and supplies. First, locate the oil pressure sending unit. This is usually located on the engine block near the oil filter.

Next, disconnect the electrical connector from the sending unit. Then, using a wrench, remove the sending unit’s mounting bolt and carefully pull the unit out of its hole.

Now that you have access to the back of the gauge, take a look at the wiring diagram that should be printed on or near the gauge.

Locate the two terminals that are labeled “send” and “ground.” Using a multimeter set to ohms (Ω), touch one lead of your multimeter to each of these terminals in turn while watching the needle on your gauge. The resistance between these two terminals should match what is listed next to “full scale” on your diagram.

If it does not, then your gauge is not working correctly and should be replaced.

If your gauge appears to be working properly, reattach the Sending Unit to its mount with its bolt, and reconnect its electrical connector.

- Make sure the engine is off and the key is out of the ignition

- Open the hood and locate the oil pressure gauge sending unit, which is usually located on top of the engine near the front

- Unscrew the sending unit with a wrench and remove it from its location

- Screw in a oil pressure gauge testing adapter in its place

- Start up the engine and let it idle for several minutes to get warm

- Check the oil pressure gauge to see if it is reading correctly

How Do You Check a Oil Pressure Gauge?

An oil pressure gauge is a valuable tool that allows you to monitor the health of your engine. By checking the pressure regularly, you can avoid costly repairs and keep your engine running smoothly.

To check your oil pressure, start by warming up your engine for about five minutes.

This will help ensure accurate readings. Then, locate the oil pressure gauge on your dash and turn on the ignition. The needle should move into the green zone or above; if it doesn’t, there may be an issue with your engine’s oil pressure.

If you’re concerned about your readings, consult a mechanic who can perform further diagnostics. Remember, catching problems early can save you time and money down the road!

How Do I Know If My Oil Pressure Gauge is Bad?

If you’re asking yourself how do I know if my oil pressure gauge is bad, then there are a few things you can check to be sure. First, look at the needle on the gauge and see if it’s pointing to zero or not moving at all. If so, then your gauge is probably broken and needs to be replaced.

Another thing you can do is start your engine and let it idle for a minute or two, then rev the engine up and see if the needle moves. If it doesn’t move at all, even when the engine is under load, then your gauge is likely broken and needs to be replaced.

How Do You Test an Oil Pressure Sender Unit?

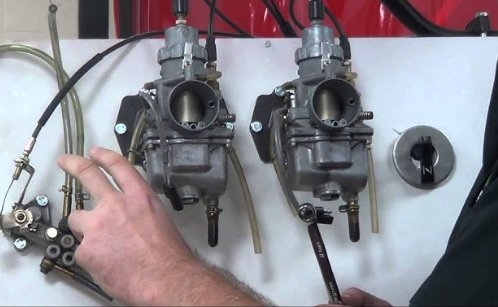

An oil pressure sender unit is responsible for sending information about the oil pressure in an engine to a gauge or warning light on the dash. There are two types of senders: mechanical and electrical.

To test a mechanical oil pressure sender, you will need a voltmeter, and to test an electrical sender, you will need a multimeter set to the ohms setting.

First, locate the oil pressure sender unit on the engine. It will be near the oil filter housing or on the side of the block. Once you have found it, disconnect the wire from the terminal.

For a mechanical testing, attach one lead of your voltmeter to the ground terminal of the sender and touch the other lead to each of the remaining terminals until you find one that produces a reading. This is your signal terminal. The reading should fluctuate between 1-5 volts as long as there is adequate oil pressure in the engine; if it doesn’t fluctuate or changes erratically, then there may be an issue with either low oil pressure or withthe sensor itself To rule out low oil pressue as teh source oof th epbfoemrn yuo can chcek tha tfirst.

. OIl pressrue can bee checked wtih adial gage screwed into teh senidng unti lport nad kleeyed off when idling adn agian when revved..

If both values are normal then replcae sensor..

For an electrical testing, touch one lead of your multimeter to any metal surface onthe engine block (this will serve as your ground) and touchthe other leadto eachof remaining terminals untilyou find one that producesa reading within specifications (usually between 70-200 ohms).

If noreading is producedor if readings are erratic, thenreplace sensor.

Can You Test a Oil Pressure Sensor With a Multimeter?

Yes, you can test an oil pressure sensor with a multimeter. You’ll need to consult your vehicle’s repair manual to find the specific location of the sensor, but once you’ve found it, you can test it by disconnecting the electrical connector and attaching the leads of your multimeter to the exposed terminals. If the sensor is working properly, you should see a reading on your multimeter that corresponds to the current oil pressure in your engine.

Oil Pressure Sensor Testing With Basic Tools – How To DIY

How to Check Oil Pressure Without Gauge

If your car is running low on oil, it’s important to check the pressure as soon as possible. However, if you don’t have a gauge, how can you tell if the pressure is low?

There are a few ways that you can check your oil pressure without a gauge.

One way is to simply listen to your engine. If it’s making strange noises or seems to be working harder than usual, this could be an indication that the oil pressure is low.

Another way to check oil pressure is by looking at the color of the oil on the dipstick.

If it’s dark and dirty, this could also be an indication of low oil pressure. Finally, if your car starts to smoke, this is definitely a sign that something isn’t right with the engine and you should get it checked out immediately.

Testing Oil Pressure Sensor With Multimeter

If your car’s oil pressure sensor is failing, it can cause a number of problems. The engine may run hot, the check engine light may come on, and the car may stall. To test whether the oil pressure sensor is failing, you can use a multimeter.

First, locate the oil pressure sensor. It will be near the engine, usually on the side of the block. Once you’ve found it, disconnect the electrical connector from the sensor.

Next, set your multimeter to ohms mode and touch one of the probes to each of the terminals on the sensor. If there is continuity between the two terminals, then the sensor is working properly. However, if there is no continuity or if the resistance reading is infinite, then that means that there is a problem with the sensor and it needs to be replaced.

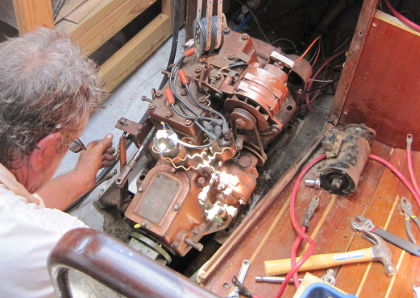

How to Test Oil Pressure Gauge on Boat

Oil pressure gauges are an important part of any boat. They help you keep an eye on your engine’s oil level and can alert you to potential problems. Periodically testing your oil pressure gauge is a good way to ensure that it is working properly.

Here’s how to do it:

1. Check the owner’s manual for your boat to find the recommended oil pressure range for your engine.

2. Start the engine and let it idle for a few minutes so that the oil has a chance to circulate.

3. Observe the needle on the oil pressure gauge. It should be within the normal range specified in your owner’s manual. If it is not, there may be a problem with your engine’s oil system.

4. Shut off the engine and wait a few minutes for the oil to drain back into the pan before checking the level with a dipstick. The dipstick should show that the oil level is at least within the “full” mark on its scale.

How to Test a 3 Wire Oil Pressure Sensor

An oil pressure sensor is a vital part of any vehicle. It helps to monitor the oil pressure in the engine, and if there is anything abnormal, it will send a signal to the computer to alert the driver. If you have a 3 wire oil pressure sensor, then you will need to test it periodically to make sure that it is working properly.

Here are some steps on how you can test a 3 wire oil pressure sensor:

1) First, take a look at the wiring diagram for your specific vehicle. This will help you identify which wires go to which terminals on the sensor.

2) Next, disconnect the negative battery cable so that you don’t accidentally short circuit anything while testing.

3) Using an ohmmeter, check for continuity between each of the three wires going into the sensor. There should be continuity between all three wires.

If there is not, then this indicates that there is a problem with the wiring or connections and further diagnosis will be necessary.

4) Now it’s time to test for resistance. With the ohmmeter still connected, put one lead on each of two opposite terminals (for example, terminal 1 and 2).

The reading should be within 10% of what is specified in the repair manual for your vehicle model year (for example, 4-6ohms). If not, replace the sensor as it has failed this portion of the test and may not be providing accurate readings anymore.

Conclusion

If your car has an oil pressure gauge, it’s important to test it regularly to make sure it’s working properly. Here’s how:

First, find the oil pressure sending unit.

It’s usually located on the side of the engine block near the oil filter.

Next, disconnect the electrical connector from the sending unit. Then, use a wrench to remove the sending unit itself.

Once the sending unit is removed, screw in a mechanical oil pressure gauge in its place. Be sure to hand-tighten only; you don’t want to over-tighten and damage the threads.

Mercedes Benz Oil Pressure Sending Unit Test Location (C107 450SL) – YouTube

Now start the engine and let it idle for a few minutes. The needle on the gauge should read somewhere between 20 and 60 psi (pounds per square inch). If it doesn’t, there may be a problem with your gauge or sending unit.

Leave a Reply